32kw/H 2000pcs/H Paper Egg Tray Making Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | Haiyang |

| Certification: | CE |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | USD 10000-50000 |

| Packaging Details: | 1. Seaworthy export packing 2. Standard export packing 3. As per customers' requirement |

| Delivery Time: | 30 days before delivery |

| Payment Terms: | T/T, L/C |

|

Detail Information |

|||

| Warranty: | One Year | Condition: | New |

|---|---|---|---|

| Production Capacity: | 1000-5000pcs Per Hour | Raw Material: | Cartons And Mixed Waste Paper. |

| Name: | Fully Automatic Paper Pulp Egg,egg Tray Forming Machine | Application: | Egg Tray Moulding/ Waste Paper Making |

| High Light: | 32kw/H Paper Egg Tray Making Machine,2000pcs/H Paper Egg Tray Making Machine,2000pcs/H pulp tray machine |

||

Product Description

Pulp Egg Tray Making Machine Egg Box Machine Paper Egg Tray Making Machine

Equipment profile

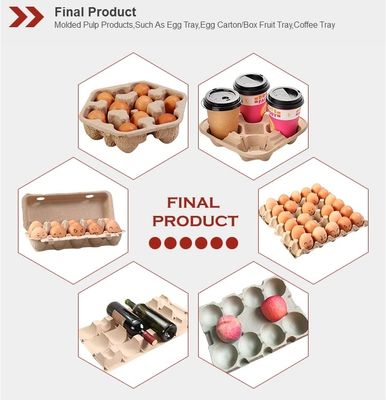

Egg tray machine uses waste paper as raw materials to produce different kinds of products according to your requirements, such as egg trays, egg cartons, egg boxes, apple trays, fruit trays, industrial trays, seeding trays etc. Our machine include pulp making system ,forming system and drying system.

This production line mainly used for the products with simple structure but in big quantity, such as egg

trays, fruit trays, cup carriers and disposable medical care products.

Product Paramenters

| Machine Model | 4*1 | 3*4 | 3*4 | 4*4 | 4*8 | 5*8 | 5*12 | 6*12 |

| Yield(p/h) | 1500 | 2000 | 2500 | 3000 | 4000 | 5000 | 6000 | 8000 |

| Waste Paper(kg/h) | 120 | 160 | 200 | 280 | 320 | 400 | 480 | 640 |

| Water(kg/h) | 300 | 380 | 450 | 560 | 650 | 750 | 900 | 1040 |

| Electricity(kw/h) | 32 | 45 | 58 | 78 | 80 | 85 | 90 | 100 |

| Workshop Area | 45 | 80 | 80 | 100 | 100 | 140 | 180 | 250 |

| Drying Area | No need | 216 | 216 | 216 | 216 | 238 | 260 | 300 |

Equipment Process

Pulping system

(1) Put the raw material into the pulper and add an appropriate amount of water for a long time to stir the waste paper into pulp and store it in the storage tank.

(2) Put the pulp in the slurry tank into the pulping tank, adjust the pulp concentration in the pulping tank, and further stir through the homogenizer through the white water of the return pool and the thick slurry of the storage tank. After adjusting to the applicable pulp, put it into the feeding pool to be used in the molding system.

2. Forming system

(1) The pulp in the supply tank is supplied into the molding machine, and is adsorbed by the vacuum system, and the pulp is left on the mold by the mold on the equipment to be formed, and the white water is sucked and transported back into the pool through the vacuum pump.

(2) After the mold is adsorbed, the transfer mold is blown out by the positive pressure of the air compressor, and the molded product is blown from the molding die to the rotary mold, and is sent out by the transfer mold.

3. Drying system

(1) Traditional drying: brick tunnel kiln, heat source can choose natural gas, diesel, coal, dry wood,A heat source such as liquefied petroleum gas.

(2) New multi-layer drying line: 6-layer metal drying line can save more than 30% energy compared to transmission drying. The main heat source is clean energy such as natural gas, diesel oil, liquefied petroleum gas and methanol.

Advantages:

1. High efficiency,low energy consume,low noise

2. Easy to operate, low labor force cost,large output

3. Stable final product quality(same weight,dimension,good look)

4. Professional technical support,superior after-sales service

5. Medium investment,high profit

6. optional color

7. excellent after-sales service

Our service

1. Pre-sale services:

1) Selecting equipment type;

2) Designing and fabricating the products in accordance with the special requirements of the clients;

3) Training technical personnel for our clients;

4) Providing construction and technology consultations or working out proper construction schemes for those new, special or difficult projects.

2. Services provided during the sale:

Respect our clients; present the clients with ease, relaxation and a surprise; devote ourselves to improve the total value of our clients.

1) Checking products acceptance ahead of delivery;

2) Introducing the service system to our clients.

![]()

![]()

![]()