30t 1500p/H 120kg/H Pulp Egg Tray Making Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | Haiyang |

| Certification: | CE |

| Model Number: | 1 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | USD 10000-50000 |

| Packaging Details: | 1. Seaworthy export packing 2. Standard export packing 3. As per customers' requirement |

| Delivery Time: | 60 days before delivery |

| Payment Terms: | T/T, L/C |

|

Detail Information |

|||

| Raw Material: | Cartons And Mixed Waste Paper.,old Carton,Carton And Newspaper | Condition: | New |

|---|---|---|---|

| Type: | Carton Used Paper Egg Tray Making Machine | Color: | Customized Color,Blue |

| Weight: | 3000kg,5t,6 Ton,30t | Warranty: | 1 Year |

| Product Type: | Egg Tray Machine | ||

| High Light: | 1500p/H pulp egg tray making machine,120kg/H pulp egg tray making machine,120kg/H egg tray manufacturing machine |

||

Product Description

Egg Carton Machine Egg Tray Making Machine Paper Pulp Egg Tray Machine

Our molding machines and molding dies are fully designed by computer-assistant engineering and high technology. It has been proven high efficiency, low maintenance and energy saving during the ten year practice. The pulp molding system can use all kinds of waste paper to produce high quality molded fibre products. Such as, egg trays, egg boxes, apple trays, meat portion trays, vegetable portion trays, fruit portion trays, strawberry punnets, kidney trays, wine packs, can trays, seed pots, seed cubes, etc. it is a satisfyingly high return investment for the entrepreneurs or investors who wants a stable and consistent business.

A complete pulp molded production line consists of Stock Preparation System Section, Molding Machine Section, Continuous Drying Oven and Conveyor System, Process Instrumentation, Instrument and Control Panels, Jobsite Installation Materials, Auxiliary Equipment, etc.

| Machine Model | 3*1 | 3*1 | 3*4 | 4*4 | 4*8 | 5*8 | 5*12 | 6*12 |

| Yield(p/h) | 1500 | 2000 | 2500 | 3000 | 4000 | 5000 | 6000 | 8000 |

| Waste Paper(kg/h) | 120 | 160 | 200 | 280 | 320 | 400 | 480 | 640 |

| Water(kg/h) | 300 | 380 | 450 | 560 | 650 | 750 | 900 | 1040 |

| Electricity(kw/h) | 32 | 45 | 58 | 78 | 80 | 85 | 90 | 100 |

| Workshop Area | 45 | 80 | 80 | 100 | 100 | 140 | 180 | 250 |

| Drying Area | No need | 216 | 216 | 216 | 216 | 238 | 260 | 300 |

Note:1. More plates ,more less water use

2. Power means the main parts,not include dryer line

3. All fuel use proportion are calculated by 60%

4. single dryer line length 42-45meter,double layer 22-25meter,multi layer can save worshop area

Equipment Process

Pulping system

(1) Put the raw material into the pulper and add an appropriate amount of water for a long time to stir the waste paper into pulp and store it in the storage tank.

(2) Put the pulp in the slurry tank into the pulping tank, adjust the pulp concentration in the pulping tank, and further stir through the homogenizer through the white water of the return pool and the thick slurry of the storage tank. After adjusting to the applicable pulp, put it into the feeding pool to be used in the molding system.

Equipment used: pulping machine, homogenizer, slurry pump, vibrating screen, pulp disintegrator

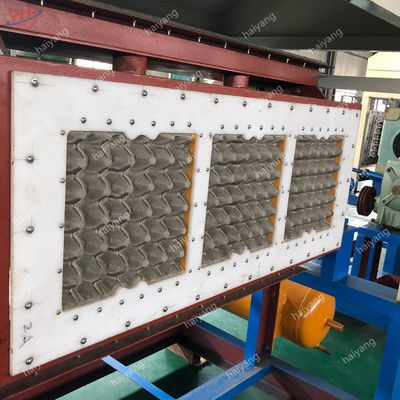

2. Forming system

(1) The pulp in the supply tank is supplied into the molding machine, and is adsorbed by the vacuum system, and the pulp is left on the mold by the mold on the equipment to be formed, and the white water is sucked and transported back into the pool through the vacuum pump.

(2) After the mold is adsorbed, the transfer mold is blown out by the positive pressure of the air compressor, and the molded product is blown from the molding die to the rotary mold, and is sent out by the transfer mold.

Equipment used: molding machine, mold, vacuum pump, vacuum tank, pump, air compressor, mold cleaning machine

3. Drying system

(1) Natural drying method: The product is dried directly by weather and natural wind.

(2) Traditional drying: brick tunnel kiln, heat source can choose natural gas, diesel, coal, dry wood,A heat source such as liquefied petroleum gas.

(3) New multi-layer drying line: 6-layer metal drying line can save more than 30% energy compared to transmission drying. The main heat source is clean energy such as natural gas, diesel oil, liquefied petroleum gas and methanol.

4. Finished product auxiliary packaging

(1) Automatic stacking machine

(2) Baler

(3) Transfer conveyor