Ply Automatic Kraft Paper Corrugated Board Plant For Wall Mounted Roll Dispenser

Product Details:

| Place of Origin: | Henan, China |

| Brand Name: | HAIYANG |

| Certification: | CE |

| Model Number: | 1092mm |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | $299000-300000 1set |

| Packaging Details: | Wooden Case and Plastic Film |

| Delivery Time: | 3-6months |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10sets per year |

|

Detail Information |

|||

| Name: | Kraft Paper Making Machine | Material: | Waste Paper ,wood Pulp |

|---|---|---|---|

| Design Speed: | 120m/min | Capacity: | 15T/D(24 Hours) |

| Brand: | Haiyang | Output Paper: | Kraft Paper, Corrugated Paper |

| Sheet Former Type: | Fourdrinier Wire | ||

| High Light: | Kraft Paper Corrugated Board Plant,Kraft Paper Board Plant 2500mm,2500mm Kraft Paper Board Plant |

||

Product Description

Products Description

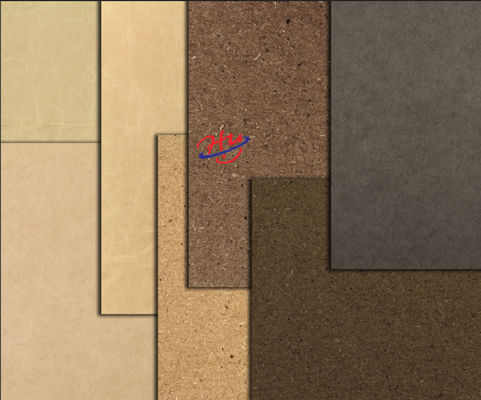

High grade waste carton recycling machine kraft liner paper machine is mainly used for making cardboard

and kraft liner paper.Paper machine is consist of headbox, wire section, press section, front drying section,

oblique surface sizing machine, back drying section, calender section, reel section. Waste carton box as

raw material, the biggest production capacity is 750t/d. Our professional engineer will design the drawings

according to your requirements.

|

1. Raw material: |

Waste paper,wood pulp,carton paper |

| 2.Product Variety: | Kraft paper ,corrugated paper |

| 3.Paper width: | 1575mm |

| 4.Quantitative: | 80-300g/㎡ |

| 5.Design speed | 120m/min |

| 6.Working speed | 80-120m/min |

| 7.Rail gauge: | 2500mm |

| 8.Transmission way: | AC variable frequency,section drive |

| 9.Arrangement: | Fourdrininer |

| 10.Capacity: | 15T/D(24hours) |

| 11.Output paper humidity: | 4%~8% |

Our Services & Strength

(1) professional engineer team with 30 years experience;skilled and careful installation team.Trade market

(2) we can supply turn-key solution without any trouble;Our company undertakes design, manufacturing, supply,

erection and commissioning of paper machines & new pulp mill and modernization of existing pulp mill and paper

machines on a turnkey basic.

(3) we have strict quality control system and ensure there is no unqualified product;

(4) professional installation technician and clear technical training for your workers;

(5) strict recalling system: if any problem of machine, we will recall it and change a new one for free;

![]()