Recycling Kraft Flute Paper Making Machine Waste Paper 500T / D 5200mm

Product Details:

| Place of Origin: | Henan, China |

| Brand Name: | HAIYANG |

| Certification: | CE |

| Model Number: | 1092mm-5200mm |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | $200000-5200000 1set |

| Packaging Details: | Wooden Case and Plastic Film |

| Delivery Time: | 3-6months |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10sets per year |

|

Detail Information |

|||

| Name: | Kraft Paper Making Machine | Material: | Waste Paper ,wood Pulp |

|---|---|---|---|

| Speed: | 60-600m/min | Capacity: | 10-500T/D(24 Hours) |

| Brand: | Haiyang | ||

| High Light: | Kraft Flute Paper Machine,500T/D Kraft Flute Paper Machine,5200mm Kraft Flute Paper Machine |

||

Product Description

Products Description

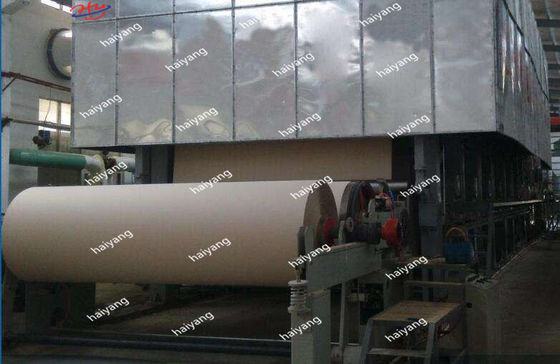

The single fourdrinier paper machine is usually used to make the high-strength and high quality

kraft paper.

The twin wire paper machine (two fourdrinier wire) is used to make the higher quality paper.

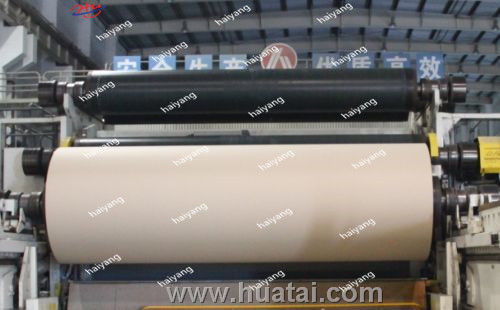

The basic components of configuration are: wire section-- vacuum pickup device (optional) --

large-diameter press section -- dryer cylinder group -- size machine -- dryer cylinder group --

reeling machine. In order to improve finished paper uniformity and ring crush index, it uses

twin wire.

Technical Specifications

|

1. Raw material: |

Waste paper,wood pulp,carton paper |

| 2.Product Variety: | Kraft paper |

| 3.Paper width: | 1092-5200mm |

| 4.Quantitative: | 80-300g/㎡ |

| 5.Design speed | 80-600m/min |

| 6.Working speed | 60-600m/min |

| 7.Rail gauge: | 2100-6200mm |

| 8.Transmission way: | AC variable frequency,section drive |

| 9.Arrangement | Single floor layout |

| 10.Capacity: | 10-500T/D(24hours) |

About Our Advantage

Technical Advantage

1.Experienced producing team

2.Advanced technological strength

Product Advantage

1.Through the international authentication

2.The same material the most preferential price

3.A lot of varieties for the customer to choose

Service Advantage

1.Technical consultation

2.Project evaluation

3.Detailed design of factory

4.Installing and testing the whole production line

5.Training engineers and workers

6.Supplying spare parts for long time

![]()

![]()