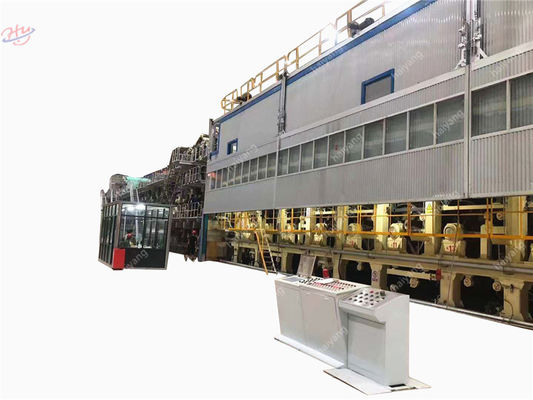

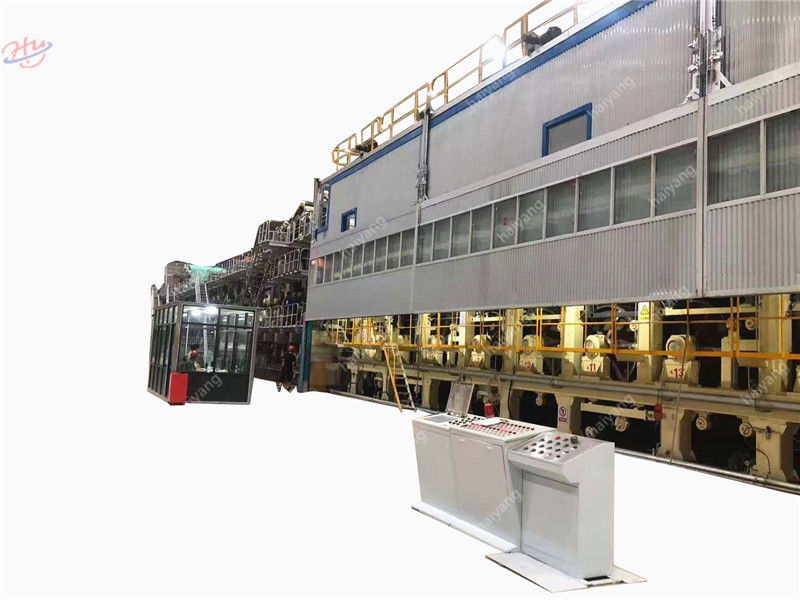

AC 2880mm 22.5m Kraft Paper Making Machinery

Product Details:

| Place of Origin: | qinyang,henan |

| Brand Name: | haiyang |

| Certification: | iso |

| Model Number: | 1500-4800 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | USD 0.2-2 million |

| Packaging Details: | WOODEN CASE |

| Delivery Time: | 25 DAYS |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 300 SETS/MONTHS |

|

Detail Information |

|||

| Product Name: | Paper Making Machine | Processing Type: | Corrugated Paper Machine |

|---|---|---|---|

| After Sales Service: | Free Spare Parts, Field Maintenance And Repair Service | Raw Material: | Waste Paper,OCC |

| Drive Way: | AC Variable Frequency Drive | Item: | Kraft Paper Making Machinery |

| High Light: | 2880mm Kraft Paper Making Machinery,22.5m Kraft Paper Making Machinery,2880mm carton box making machine |

||

Product Description

waste old carton box recycled craft paper making

machine/kraft paper making machine

The machine will adopt the commodity wood pulp to produce Kraft paper.This production

line is composed of three components, namely pulping equipment,paper making machine

and finishing equipment.The details of name,quantity,unit price,total amount, matched motor

for each part of the production line.

Technical parameter:

1. Raw materials: recycled paper, wood pulp

2. Output paper: corrugated paper ;kraft paper ;liner paper

3. Output paper weight:70-150g/m2

4. Capacity: 80 T/D

5. Fourdrinier wire width:3350mm

6. Net paper width:2880mm

7. Drive way: Alternating current frequency converter speed control, sectional drive.

craft paper machine price

Main frame of equipments:

1. Fourdrinier part: 16m fourdrinier table, the frame coated by stainless steel.

2. Dryer part: dryer cylinder 20 sets .

3. Calendaring part: three-roll calendar 1 set.

4. Winding and rewinding part: 1 set of Horizontal winding machine with winding

cylinder ,1 set of high duty frame type rewinding machine.

Main equipments of paper making machine:

| NO. | Item | quantity(set) |

| 1 | 2880mm Multi-cylinder Fourdrinier paper making machine | 1 |

| 2 | Dryer part exhaust hood | 1 |

| 3 | Propeller fan | 4 |

| 4 | Vacuum suction box | 9 |

| 5 | 2880mm three-roll calendar | 1 |

| 6 | 2880mm Horizontal winding machine | 1 |

| 7 | 2880mm Frame type rewinding machine | 1 |

| 8 | Air compressor | 1 |

| 9 | Air tank | 1 |

| 10 | Frequency conversion controlling cabinet | 1 |

| 11 | Automatic quantitative scanner | 1 |

| 12 | The whole set of working platform |

![]()

![]()

![]()