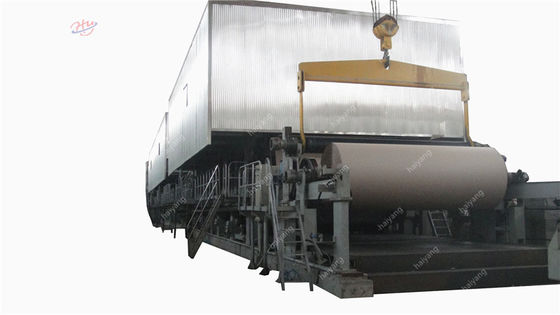

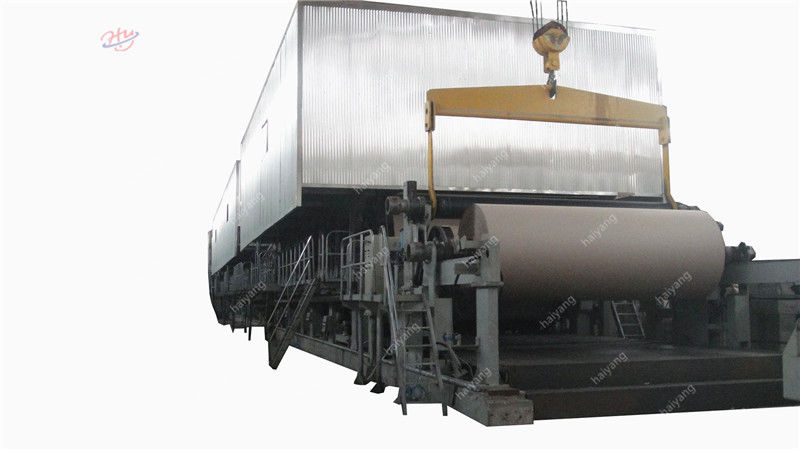

300gsm 4400mm 350m/Min Wood Pulp Making Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | HAIYANG |

| Certification: | CE |

| Model Number: | 4200MM |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 SET |

|---|---|

| Price: | USD 0.2-2 million |

| Packaging Details: | EXPORT STANDARD PACKAGE |

| Delivery Time: | 180 DAYS |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 20 SETS PER YEAR |

|

Detail Information |

|||

| Raw Material: | Waste Paper ,wood Pulp | Net Paper Width: | 4400mm |

|---|---|---|---|

| Capacity: | 200 T/D | Working Speed: | 150-350m/min |

| Gauge: | 5400mm | Paper Weight: | 100-300gsm |

| Design Speed: | 400m/min | ||

| High Light: | 4400mm wood pulp making machine,350m/min wood pulp making machine,350m/min kraft paper manufacturing machine |

||

Product Description

4400mm Waste Paper Wood Pulp Kraft Paper And Testliner

Paper White Top Paper Making Machine

|

1 |

Output paper |

kraft corrugated paper, testliner paper,white kraft paper |

|

2 |

Raw material |

waste paper, old carton box, wood pulp, straw |

|

3 |

Capacity |

200T/d |

|

4 |

paper weight |

100-300G/M2 |

|

5 |

Net paper width |

4400mm (adjust according to clients’ requirement) |

|

6 |

Rail space |

5400mm |

|

7 |

Working Speed |

150-350m/min

|

|

8 |

Design Speed |

400m/min |

|

9 |

Drive and control |

Alternating current, frequency conversion, speed control, section drive ; |

Process flow

waste paper → high consistency hydrapulper → high frequency vibrating screen

→ pulp pump → efficient double disc pulp refiner → pulp pump → chest agitator

→ pulp pump → centrifugal screen → pulp pump → impurity remover → paper

machine → calendar → winding machine → rewinding machine

Characteristic of recycling machine for paper

Headbox

• Excellent component element intefration, unique flow channel design. The special

flow channel can jet the pulp evenly, and no fiber and dust stayed.

• Adjustable slice angle designed, is can be adjusted at any time.

• Rotproof stainless steal, durable usage time.

• Multi-material adoption, high efficiency.

• Basic Weight

Suction Cylinder

• Special design for hole drilling, insure high efficient water dehydration..

• Steam and water automatic separate design, minimize ther energy consumption.

• Rotproof stainless steal, durable usage time.

Suction Touch Roll

• The roll is covered by polyurethane, and with groove on the surface

• After the suction touch roll, the water dehydraton can up to 36%

• Suction Box

High efficiency and durable.

• Vacuum Pump

Low energy consumption, low maintain cost and low noise. Double vacuum pump,

helping the operator has better control and monitoring the machine.

• Horizontal Screen

High precision, High efficiency and Muli-material adoption.

• Fan pump

Low-pulse, low energy consumption and stable flow pumping.

• Horizontal Wave Doctor Blade System

Enhance the blade duration time and reduce the paper break frequency and protect

the Yankee Cylinder.

• PEO Supply System

Mix the pulp and PEO fatly and evenly.

![]()

![]()

![]()