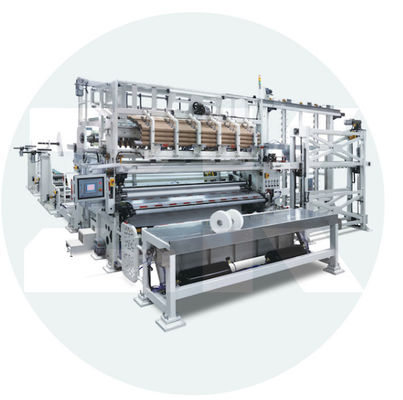

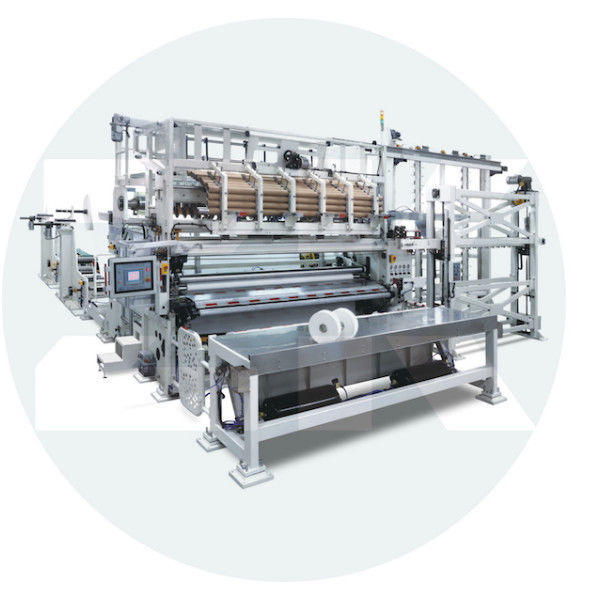

Rewinder Toilet Paper Making Machine Automatic High Speed Industrial Roll Slitting

Product Details:

| Place of Origin: | Henan, China |

| Brand Name: | HAIYANG |

| Certification: | CE |

| Model Number: | 1575mm |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1set |

|---|---|

| Price: | $10900-11000 1set |

| Packaging Details: | Wooden Case and Plastic Film |

| Delivery Time: | 1-3months |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 200sets per year |

|

Detail Information |

|||

| Name: | Paper Rewinding Machine | Capacity: | 2T/D(8hours) |

|---|---|---|---|

| Control Model: | Automatic | Enbossing Condition: | Rubber Roller |

| Function: | Multi-function | Type Of Toilet Paper: | With Core Or Coreless |

| Packing: | Wooden Case And Plastic Film | Brand: | Haiyang |

| Country Of Origin: | China | Shipment: | By Sea |

| High Light: | Rewinder toilet paper making machine,Slitting Rewinder toilet paper machine,2T/D toilet paper making machine |

||

Product Description

Products Description

1. With adopted PLC and HMI technology, it is easy to operate this machine.

2. There are automatic core feeding system, automatic pull/plug shaft system and automatic cutting core system.

3. The machine production process: core convey, shaft plugging, core feeding, slitting and rewinding, tail trimming and sealing, shaft puling.

4. Each unit is driven by an independent servomotor. Simple structure decreases the failure rate.

5. Rewinding control: Automatic pneumatic proportional valve controls linear slider rail lifting, pneumatic servo system controls riding roller, pneumatic thimbles grasp core shaft.

6. Front & back rewinding rollers’ speed differential and riding roller control the final product’s tension and both ends’ neatness. The slitting blade is precisely controlled, with the tolerance of ±0.1mm.

| Machine model | 1575mm | 1760mm | 1880mm | 2800mm | 3500mm |

| Paper width(≤mm) | 1800mm | 2000mm | 2200mm | 2800mm | 3500mm |

| 1. Finished diameter (mm) | φ50~1800mm Adjustable Width |

| 2. Finish paper core: | φ30~55mm |

| 3.Base Diameter | 1100mm Standard(Other size are available) |

| 4.Jumbo Roll Core Diameter | 76mm Jumbo Roll Core Diameter |

| 5.Process Capability | 150~280 M / Minute |

| 6.Parameter Setting | PLC computer operating system interface |

| 7.Back Stand | Standard three layersynchronous transmission |

| 8.Perforation Pitch | 2blades,150~300mm ;3blades,80~220mm |

| 9.Power | 5.5kw~15kw Stepless variable speed |

| 10.Dimensions | 6200x2600x800mm~6200x4000x800mm |

| 11.Weight | 2300kg~3800kg |

FEATURES

- Slitting unit which contains one set of slitting knives.

- Embossing unit having metal to paper ball type in either full or border pattern.

- Electronic counting for absolute accuracy.

- Separation between stacks with single napkin lift which is operated pneumatically.

- Integrated Band Saw to cut two lanes into four stack on delivery deck.

- Blade sharpening.

- Pneumatic lifting arms to load parent roll.

![]()

(2) we can supply turn-key solution without any trouble;

(3) we have strict quality control system and ensure there is no unqualified product;

(4) professional installation technician and clear technical training for your workers;

(5) strict recalling system: if any problem of machine, we will recall it and change a new one for fre

This equipment can process raw paper of 1575mm,1800mm,2000mm,2200mm,2800mm,3500mm in width. There are two types of this model:one is ordinary type, it used one embossed unit for 2 ply paper, and the other is dot-by-dot type, it used embossed units respectally for each one.

This machine is consist of stand of raw material, paper conveying unit, embossing unit, perforating unit, rolling unit,electricity control and cutting system. The production process is : unreeling -→ embossing -→perforating-→furl-→slitting.

Yolanda

Sales manager

Qinyang City Friends Machinery Equipment Co., Ltd

https://www.frdpapermachine.com/