22 Dryer 2400mm 200g/M2 Kraft Paper Making Machinery

Product Details:

| Place of Origin: | qinyang,henan |

| Brand Name: | haiyang |

| Certification: | iso |

| Model Number: | 2400 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | USD 0.2-2 million |

| Packaging Details: | WOODEN CASE |

| Delivery Time: | 60 days |

| Supply Ability: | 300 SETS/MONTHS |

|

Detail Information |

|||

| Name: | Kraft Liner Paper Machine, Paper Recycling Machine | Raw Material: | Waste Paper, Virgin Pulp, OCC |

|---|---|---|---|

| Finished Paper: | Kraft Paper, Craft Paper, Duplex Board Paper, Testliner Paper | Net Paper Width: | 2400mm |

| Rail Gauge: | 3400mm | Processing Type: | Paper Making Machinery Production Line |

| High Light: | 2400mm Kraft Paper Making Machinery,200g/m2 Kraft Paper Making Machinery,2400mm kraft paper manufacturing machine |

||

Product Description

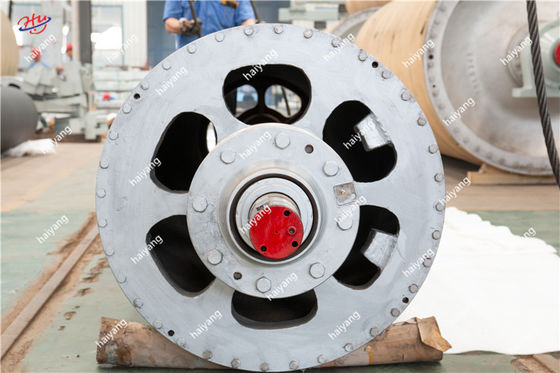

2400mm high speed craft paper making machine kraft liner

paper machine paper recycling machine

Paper making machine introduction:

It is mainly used for paper making (recycling paper making machine), such as kraft

paper making, corrugated paper making and so on .we can offer the whole line of

paper making.

Main technical data:

1. Paper type: craft paper

2. Gram weight: 80-200g/m2

3. Trimmed width: 3200mm

4. Designed speed: 100-180m/min

5. Production capacity: 100t/d

6. Design speed:230m/min

7. Dryness:

After wire section: ≥18-21%

After press section: ≥38-42%

Paper product dryness: 90%-92%

8. Finished product ratio: 96%

Paper machine features:

1. This paper machine is equipped with dewatering element according to max.

basic weight and pulp type.

2. The production capacity can be assured. When the paper making basic weight

is changing, the vacuum degree of vacuum dewatering element can be adjusted to

make sure the paper dryness. According to the vacuum degree from low to high,

equipped with forming board, dehydrate box, vacuum dehydrate box, low vacuum

suction box(wet suction box), high vacuum suction box(suction box).

3. Material of elements that contact with wire is ceramic material. Front of scraper

blade is flat. Box is stainless steel. Each vacuum suction box is equipped with steam

separator and connect with vacuum main pipe.

![]()

![]()

![]()

![]()

![]()

![]()

![]()