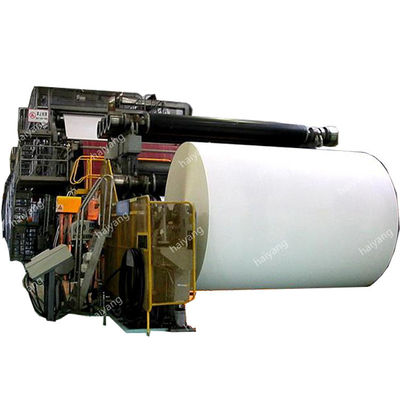

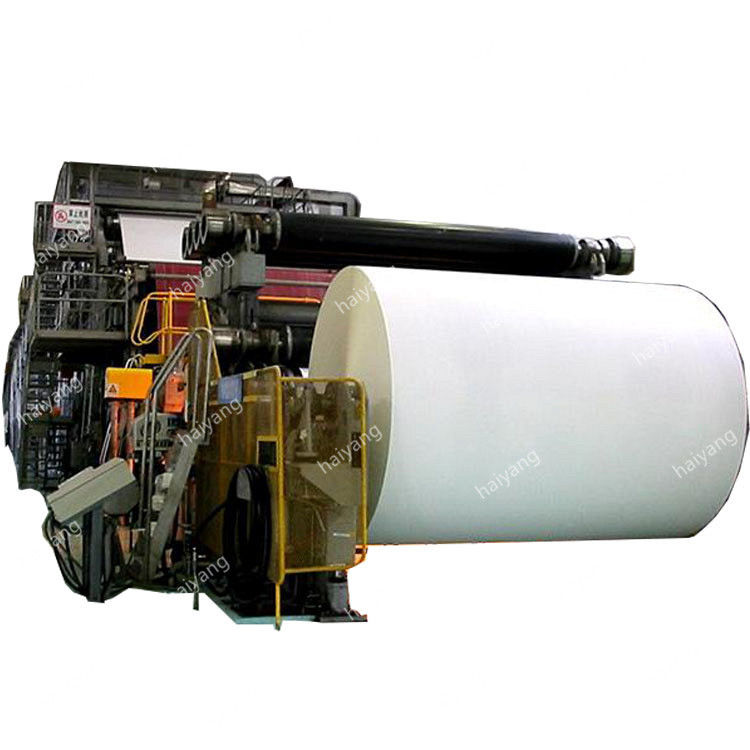

Waste Paper 3200mm 280m/Min A4 Paper Making Machine

Product Details:

| Place of Origin: | Qinyang City,China |

| Certification: | CE; ISO9001 |

| Model Number: | 3200mm |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1set |

|---|---|

| Price: | USD 0.2-2 million |

| Packaging Details: | Wooden Case In Containers |

| Delivery Time: | three months |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 1set per three months |

|

Detail Information |

|||

| Material: | Waste Paper | Condition: | New Condition |

|---|---|---|---|

| Automatic Level: | Top Automatic | Driven Type: | Pneumatic&Electricity |

| Product Item: | Paper Making Machine | Final Product: | Culture Large Roll Paper |

| High Light: | 280m/min A4 Paper Making Machine,3200mm A4 Paper Making Machine,3200mm office paper making machine |

||

Product Description

3200mm Culture Writing Paper Making Machinery With Resonable Price / Office Paper Making Machinery

Product Details

![]()

| Paper Width | 3200mm |

| Working Speed | 150-280m/min |

| Papermaking Quantitative | 50-80g/m2 |

| Contral System | 50-80T |

| Contral System | PLC, Frequency Converter |

| Drive Way | Electric Motor |

| Raw Material | Waste paper/ Wood/Straw /Reed |

| Finished Products | Culture /A4 / Writing Paper |

| Color | As per Choice |

| Application | Paper Making Industry |

| Product Keywords | typing paper making machine, fourdrinier machine |

This Production Line can use different kinds of waste paper,recycled paper,wood pulp, as material to produce cultural paper, finished product can be big cultural paper roll.

![]()

Pulp Making Equipment Configuration

| All The Equipments |

| Name | Quantity |

| 12m3 High-Density Pulper | 1 |

| 12m Conveyor | 1 |

| 3 m2 Vibration Screen | 1 |

| Mesh Screen | 1 |

| 50m3 Potcher | 6 |

| dia 1200 Impeller | 8 |

| 350 double-disk Refiner | 2 |

| Double-entry Pump—200 | 1 |

| 606 Sand Remover-8pieces | 1 |

| 3m²Centrifugal Screen | 1 |

| 150type Pressure Screen | 1 |

| Pulp Pump 250 | 4 |

| Pulp Pump 160 | 10 |

| High-Pressure Pump 120 | 1 |

Function

| NO. | Name | Function |

| 1 | Stainless Steel Cylinder Mold | Extract the pulp fiber to felt |

| 2 | Alloy Dryer Cylinder | Dry the wet paper |

| 3 | Double-layer Dryer Hood | Cover dryer and collect the hot&moist air diffused by dryer |

| 4 | Axial-flow Ventilator | Ventilate and pull out the hot&moist air in the exhaust hood |

| 5 | Roots Vacuum Pump | Provide vacuum force for suction box |

| 6 | Air Compressor | Provide compressed air for pneumatic devices |

| 7 | Frequency Conversion Controlling Cabinet | Control the speed of the machine |

| 8 | Vacuum Suction Box | Absorb water contained in the wet paper |

| 9 | High concentration hydrapulper | Break the waste paper into pulp |

| 10 | High Frequency Vibrating Screen | Separate and remove large impurity in the pulp |

| 11 | Propeller | Stir pulp and keep pulp well-mixed with water |

| 12 | Pressure Screen | Getting ride of impurities |

| 13 | Bleacher | Bleach and whiten pulp |

| 14 | Double Disc Refiner | Grind, refine and fibrillation |

| 15 | Low Concentration Sand Remover | Remove sand and impurities |

| 16 | Pulp Pump | Pulp transportation |

| 17 | Electrical Operation Cabinet | Control machine operation |

| 18 | Boiler | Provide steam for the drying section |

Packaging&Shipping

![]()

![]()

![]()

Want to Know more details about this product