Vacuum Foil 3.86g/Cm3 15Gpa Paper Plate Machine Parts

Product Details:

| Place of Origin: | Qingyang City,Henan |

| Certification: | CE;ISO9001 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1set |

|---|---|

| Price: | USD 10000-50000 |

| Packaging Details: | Wooden Case with Poly Film Wrapping |

| Delivery Time: | 10days |

| Payment Terms: | T/T, L/C, Western Union, MoneyGram |

|

Detail Information |

|||

| Material: | Stainless Steel 304;Ceramic (99% Alumina, FRP Base) | Strip: | 3 Pieces;5 Pieces |

|---|---|---|---|

| Usage: | Dewatering For Forming Section Of Paper Machine | Surface Treatment:: | Polishing |

| High Light: | Vacuum Foil 15Gpa paper plate machine parts,3.86g/cm3 paper plate machine parts,3.86g/cm3 corrugated box stitching machine spare parts |

||

Product Description

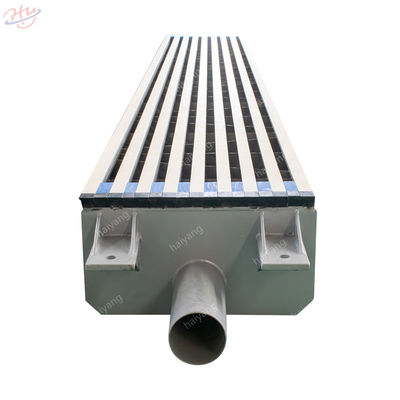

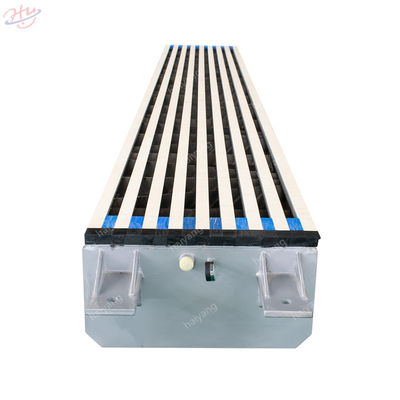

Vacuum Foil with Ceramic Cover Dewatering Elements for Paper Making Machine

Product Intrduction

A foil elements consists of a stationary blade fitted below the wire ,the upper side of which forms a small expansion angle with the wire ,generating an under pressure.However ,by choosing a small enough angle ,sometimes below one degree,a suitable suction pressure can be generated even at high wire speed.The accurate angle plays a great role during the dewatering process.

Technical Parameters

| Item | Unit | Data |

| Bulk Density | g/cm3 | 3.86 |

| Hardness (HV) | Gpa | >14.7 |

| Bending Strength | MPa | ≥360 |

| Fracture Toughness | MPa | 5-6 Mpa.m 1/2 |

| Coefficient of thermal Expansion | 7.0-7.5x10-6.0c | |

| Water Absorption | % | <0.025% |

| Surface Roughness | --- | ≤0.5μm |

| Particle Size | Submicron | |

| Porosity | % | <0.04% |

Product Details Show

![]()

2. Low Friction Coefficient

3. Stable Structure-Tray-frame

4. Firmly fFxed Structure

5. Easy to Replace

6. Low Sdhesive Rate For Mixtures

7. Choices for the Percentage of Opening

8. Lubricant Equipment

9. Movable Bar

10. Efffectively Protect Forming Wire

11. Long Serive Life

![]()

2. Impact Resistance (up to 170KJ/m m2)

3. Self-lubrication

4. Hydrophobic Property

5. Not Easy Adhesion

6. Absorb Impact Energy

7. Tensile Strength

2. What should I have to know if I want to get the quotation?

(1) What kind of raw material you will use(main important)

(2) The capacity you want produce per day (main important)

(3) The paper weight you require

(3) The paper width you require

training, our company can supply for you all

5. Q:How is your Payment Term ?

A:Generally, our payment term is T/T 30% in advance and the balance 70% before the delivery

6. Q:Can you make paper mill design for us?

A:Yes, we have professional team with rich experience of paper mill design by CAD software. Paper mill dewatering elements